Choosing the right safety glasses is essential for ensuring effective eye protection in various environments and activities. Here are some steps to help you select the appropriate safety glasses:

- Identify the Hazards: First, identify the specific hazards you will encounter. Different situations require different types of safety glasses. Common hazards include impact from flying debris, chemical splashes, UV radiation, optical radiation, and more.

- Understand ANSI Ratings: In the United States, the American National Standards Institute (ANSI) sets safety standards for eyewear. Look for safety glasses that meet ANSI Z87.1 standards, as this ensures they provide adequate protection against impact and other hazards.

- Consider Lens Material: Safety glasses typically use polycarbonate lenses because they are impact-resistant and lightweight. Polycarbonate lenses are ideal for protection against flying debris and other impacts.

- Lens Coatings: Consider any additional lens coatings that may be necessary for your environment. Common coatings include anti-fog, anti-scratch, anti-UV, and anti-glare coatings. These coatings can enhance comfort and extend the life of the glasses.

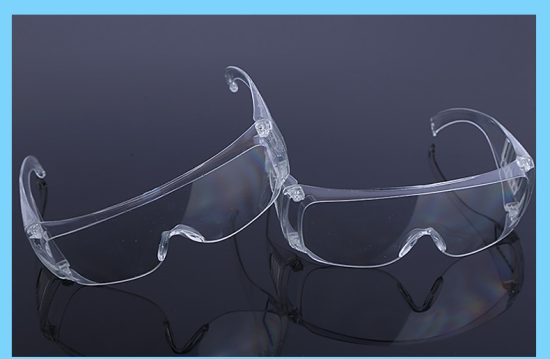

- Frame Design: Choose a frame design that fits comfortably and securely on your face. Look for adjustable features like nose bridges and temples to ensure a proper fit. Some safety glasses have cushioning for added comfort.

- Ventilation: Depending on your environment, ventilation may be important to prevent fogging. Ventilated safety glasses help maintain clear vision, especially in situations with temperature changes.

- Tint or Shade: If you work outdoors or in bright environments, consider safety glasses with tinted or shaded lenses to protect against harmful UV rays and glare.

- Prescription Glasses: If you wear prescription glasses, consider safety glasses that can accommodate your prescription. Many safety glasses can be fitted with prescription lenses or come in prescription-ready versions.

- Compliance Labels: Ensure that the safety glasses have compliance labels or markings indicating that they meet the appropriate safety standards (e.g., ANSI Z87.1). This ensures that the glasses provide the required level of protection.

- Activity-Specific Glasses: Some activities, such as welding or laser work, require specialized safety glasses designed to protect against specific hazards. Ensure that you use glasses designed for the task at hand.

- Try Before You Buy: If possible, try on safety glasses before purchasing them to ensure they are comfortable and fit securely. If buying online, check for a return policy in case they don’t fit as expected.

- Replace When Necessary: Over time, safety glasses may become scratched, damaged, or lose their effectiveness. Replace them when they show signs of wear and tear to maintain adequate protection.

Remember that safety glasses are a critical investment in protecting your vision, so it’s important not to compromise on quality or fit. By carefully considering your specific needs and environment, you can choose the right safety glasses that provide the best protection for your eyes.